About Us

Caboolture Powder Coating for Local & Brisbane Customers

We Have An Eye For Detail

We are a young, dynamic company eager to provide the best quality work we can for our customers.

Family Owned and Operated

Quick Turnaround

Quality Work

Large Clean Factory

Capable of completing both large & small jobs

Fully Insured

our workshop

oven

& tracking

oven

spray booth

pre-treatment

tanks

Domestic, Commercial & Industrial Powder Coating

Call us at 07 5412 0304 or Send us a message for any Powder Coating Services

Powder Coating Work We Do

We can handle small jobs like your car’s wheel rims to very large, industrial work. And we have dedicated equipment to meet your requirements for a perfect job.

Equipment

Gema Optiflex 2 Powder Coating Gun

Emjay Spray Booth with full extraction system

Emjay 4 tank Pre-treatment tank setup with overhead gantry and PH system

Emjay Industrial Oven with optional extension

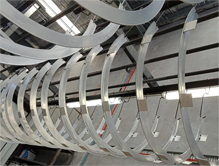

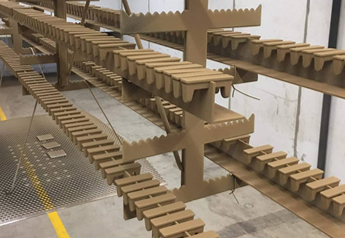

Emjay Tracking System from hanging through to cooling

Oven with extension can take various items up to 8.0m long

*Depends on items hanging options

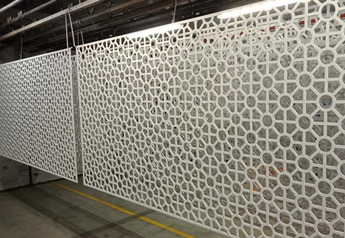

Our large workshop can handle all your work! We Powder Coat:

Flashings

CNC Sheets / Perforated Sheets

Louver Screens

Batten Screens

Extrusion (Short and long lengths)

Box Section (SHS,RHS)

Angle

Posts & Beams

Building components

Vehicle & Bike Rims

Folded & Flat Sheet

Bull Bars

Chairs + Tables

Interior Design Components & Shop Fittings

Just to name a few….

Domestic, Commercial & Industrial Powder Coating

Call us at 07 5412 0304 or Send us a message for any Powder Coating Services

Powder Coating Process

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat.

It is usually used to create a hard finish that is tougher than conventional paint.

Powder coating is mainly used for coating of metals, such as household appliances, aluminium extrusions, aluminium screens, hardware, automobile and bicycle parts.

Advantages over other coating processes:

1. Powder coatings contain no solvents and release little or no amount of volatile organic compounds (VOC) into the atmosphere. Thus, there is no need for finishers to buy costly pollution control equipment. Companies can comply more easily and economically with the regulations of the U.S. Environmental Protection Agency.

2. Powder coatings can produce much thicker coatings than conventional liquid coatings without running or sagging.

3. Powder coated items generally have fewer appearance differences than liquid coated items between horizontally coated surfaces and vertically coated surfaces.

4. A wide range of speciality effects are easily accomplished using powder coatings that would be impossible to achieve with other coating processes.

5. Curing time is significantly faster with powder coating than with liquid coating.

powder coating process basic steps

Part preparation processes and equipment

Removal of oil, dirt, lubrication greases, metal oxides, welding scale etc. is essential prior to the powder coating process. It can be done by a variety of chemical and mechanical methods. The selection of the method depends on the size and the material of the part to be powder coated, the type of impurities to be removed and the performance requirement of the finished product.

Chemical pre-treatments involve the use of phosphates or chromates in submersion or spray application. These often occur in multiple stages and consist of degreasing, etching, de-smutting, various rinses and the final phosphating or chromating of the substrate and new nanotechnology chemical bonding. The pre-treatment process both cleans and improves bonding of the powder to the metal.

Different powder coating applications can require alternative methods of preparation such as abrasive blasting prior to coating.

Powder application processes

The most common way of applying the powder coating to metal objects is to spray the powder using an electrostatic gun.

The gun imparts a positive electric charge to the powder, which is then sprayed towards the grounded object by mechanical or compressed air spraying and then accelerated toward the workpiece by the powerful electrostatic charge. There is a wide variety of spray nozzles available for use in electrostatic coating. The type of nozzle used will depend on the shape of the workpiece to be painted and the consistency of the paint. The object is then heated, and the powder melts into a uniform film, and is then cooled to form a hard coating. It is also common to heat the metal first and then spray the powder onto the hot substrate.

Curing

When a thermoset powder is exposed to elevated temperature, it begins to melt, flows out, and then chemically reacts to form a higher molecular weight polymer in a network-like structure. This cure process, called crosslinking, requires a certain temperature for a certain length of time in order to reach full cure and establish the full film properties for which the material was designed. Normally the powders cure at 200 °C (390 °F) for 10 minutes. The curing schedule could vary according to the manufacturer’s specifications. The application of energy to the product to be cured can be accomplished by convection cure ovens, infrared cure ovens, or by laser curing process. The latter demonstrates significant reduction of curing time.

Domestic, Commercial & Industrial Powder Coating

Call us at 07 5412 0304 or Send us a message for any Powder Coating Services

Domestic, Commercial & Industrial Powder Coating

Call us at 07 5412 0304 or Send us a message for any Powder Coating Services

what our clients say

Outstanding is an understatement, very well priced and very high quality finish on our job, thank you Lauren & team

Highly recommended and a highly quality product with an awesome turnaround time and top people to deal with

The quality is second to none as is the service.

Very helpful staff and the factory is very clean and organized. They have an EYE on quality.

Hawk Eye Coatings are very professional and produce an excellent quality product

CONTACT US

Get in touch with Hawk Eye Powder Coating Pty Ltd on

07 5412 0304

for exceptional metal coating services.

You Can Find Us Here

Unit 2/8-10 Skyreach St, Caboolture QLD 4510, Australia

Hawkeye Powder Coating © 2019. ABN 70 630 228 296. All rights reserved. Website Design by Morningstar Digital